The Background

The Ralph Draughon Library at Auburn University is the design of Davis, Speake and Associates, Architects of Birmingham. Well, in 1983, Auburn decided to double the library in size and PH&J got the job. Our then new field man, David Atkins, drew the assignment during construction, and thus he tumbles into this tale of woe once again.

Our design for the library addition incorporated an array of precast concrete wall panels for which the Castone Corporation of Opelika was subcontractor for manufacture and erection. The president of Castone was one David James, a cousin of Governor Fob James, who tended to operate his business as much by political clout as by merit. I never actually saw the library panels nor did I ever talk to David James, but according to Atkins, several of the panels sustained severe damage during transport or erection and were rejected. Our specification for these panels required that they be replaced; patching was not allowed.

James flew into a rage in the face of PH&J’s rejection, and refused to replace the panels, insisting that he be allowed to make field repairs where the broken corners occurred. David Atkins and PH&J stood firm and a confrontation of considerable magnitude ensued. Auburn’s entire Building and Grounds staff cheered us on, noting that in the history of the University, not a single field patch of precast concrete had ever been successful. Faced with this standoff, James approached Auburn President Harry Philpot and whined that he was being treated unfairly. James must have been a big contributor, because Atkins, PH&J and Auburn’s own B&G Department were all overruled by Philpot.

Feeling righteously indignant and put-upon, PH&J (abetted by yours truly) declared that its precast concrete specifications were clear, fair and justified, and vowed that the Castone Corporation would never again be allowed to bid PH&J work. David James said that was fine with him and swore that he would never again submit one.

Overruled Once Again

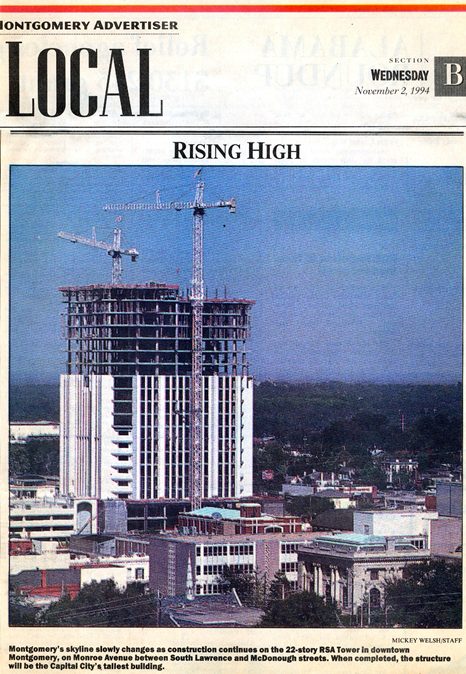

For the next eight years David James stuck to his word and we to ours. PH&J was not bothered by Castone on the Montgomery County Jail and Courthouse, nor on the RSA Plaza, nor the ACC, all of which were clad in precast concrete. But in 1992, when Bronner announced yet another round of buildings, this time entailing $100 Million, it was more than James could bear. He was losing too much business.

In September of 1992 David James wrote me and asked that PH&J qualify his Opelika Company to bid the RSA Union and Tower. I said hell no, and James set off on his usual path. He persuaded his State Representative, Pete Turnham, to beseech Dr. Bronner to direct yours truly to approve Castone Corporation (which by that time had done work all over the South).

He asked Paul Hubbert, Chairman of the RSA Teachers Board of Control, to make the same request. Hubbert was head of the Alabama Education Association (Teacher’s Union), and Castone had recently done the precast cladding of the AEA’s new building on Dexter Avenue. James even managed to reach Governor Guy Hunt, who was chairman of the other RSA Board. Bronner, who had been absolutely dogmatic that we allow only quality subs to bid, was supportive of my position, but the political pressure was getting heavy. Finally, after enduring weeks of harassment, he called me in and said I would have to approve the Castone Corporation.

Feeling depressed at having been overcome politically a second time, I returned to the office to plot a next move. A day or so later, after David Atkins and I had done a little research, I called Bronner back and demanded that, if he was going to make me approve Castone, he should at least ride downtown with me and inspect some of their work. Bronner agreed and Atkins and I escorted him to the new AEA office structure. Atkins and I had that morning scouted the building and we knew exactly where to point out some dreadful precast work that Castone had done.

After a few moments, we had Bronner gasping in dismay. As we left Dexter Avenue he blurted out, “I’m not going to have crap like that–I’m trying to build 50-year buildings–don’t approve them.” David Atkins and I exchanged smug glances.

Atkins and I were premature in our gloating, because David James was not through. He convinced Ron Blount that this was just a personal fight between himself and me, even though I had never met the man and was not really involved in the Auburn Library melee that started the feud. Next James managed to involve his cousin, ex-governor Fob James, and even Mayor Freeman of Opelika. They, plus Turnham, Paul Hubbert and Governor Hunt were apparently too much. Dr. Bronner now had to reverse himself a second time and direct that Castone be allowed to bid. I goaded Bronner by asking if every precast bidder would be allowed to produce work that sorry, or just Castone of Opelika. Bronner snorted in reply.

Bronner’s formal memo to me on the subject, dated December 16, 1992, was a classic. In it he quoted from his message to Mayor Freeman which reminded all that “David James personally guaranteed PH&J that he would never bid another PH&J job”. He went on to say “Castone will be permitted to bid on the condition that (1) Mr. David James will not be permitted to have any contact with PH&J nor will he be allowed on the job site in Montgomery, and (2) David James, Jr., will set up a meeting with Humphries and Ron Blount to furnish evidence of his company’s ability to provide a quality product.”

A few days later David James, Jr., appeared, hat-in-hand, to take a whipping for his daddy. We warned David Jr. that if a panel was damaged he got to recast it. I also told him to tell the Senior David that “he had better get to know lots of politicians, because that sure as hell is the only way you’ll ever get to bid our projects in the future.”

The Outcome

The Outcome

Castone bid the RSA Union but was not low, so we escaped that bullet. However, when we bid the Tower, our luck ran out and David James got the job. The biggest cast concrete panel job PH&J ever had–ever would have–and we have to put up with Castone of Opelika!

I will give the devil his due. Perhaps it was the pressure that we put on the company via our weekly visits to the Opelika plant, or maybe it was the threats from David Bronner, but I admit that David James and son did a better job for us than on any job they had ever done before. But don’t get the wrong idea–they still screwed up big-time. Castone solved most of the problems that had plagued us before, but they managed to concoct replacement calamities for our Tower job.

David James and PH&J’s Architectural Designer on the Tower, John Gandy, cavort on a flatbed ready to leave the Castone plant in Opelika, heading for the Tower.

First and foremost, they failed to cull their mix aggregate and allowed ferrous bearing “rust rocks” into the concrete. That is Ned in the first reader stuff. Now when you look closely at the Tower’s exterior skin you can see over a hundred of these of little orange rust streaks running down the white surface where one of these ferrous rocks is too close to the surface of the concrete panels.

Second, the fools cast recessed lifting loops, so called “Burke anchors”, into the visible face of some 80 slope sill surfaces that occur on the building corners. These are made of steel and ultimately will rust and stain seriously. On 50 previous cast stone projects, no manufacturer had ever cast anchors in an exposed face. PH&J forced Castone to employ a concrete restoration specialist out of Irving, Texas, to direct the field patching of these recesses and thus cover the steel loops with protective concrete. However, we well know that the patches will finally fail and the problem will assume its true magnitude. I say this despite the 20-year guarantee we extracted from Castone against patch failure, patch discoloration or rust stain.

Third, when the building was staged near its completion to allow us to check the joint sealant work, our party noted that the return legs of many precast panels were splitting off. Such hairline fractures are quite common in precast work, but usually do not show up until five years have passed. I won’t even speculate on where this one is going.

Yours truly will not sweat the precast problems. RSA allowed politics to interject itself into the process and must reap what was sown.

-Charles Humphries (“Peril and Intrigue Within Architecture”)

This is one of many RSA Tower stories. The rest can be found here.